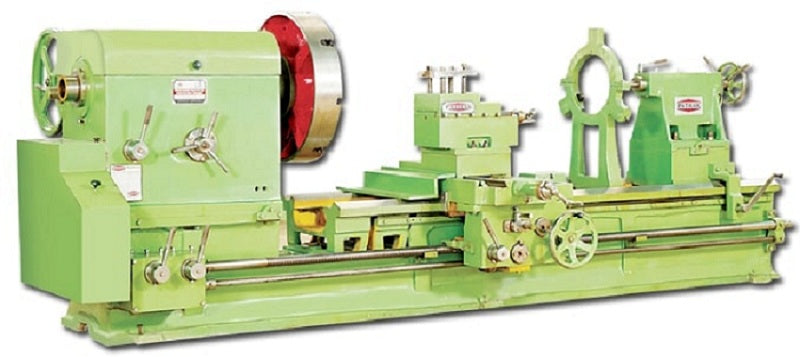

Detailed Information and Advantages of Heavy Duty Lathe Machine

A heavy-duty lathe can spin a workpiece around its axis to execute activities like slicing, cutting, and drilling.

A heavy-duty lathe is not a stand-alone unit. High duty lathes are a special type of lathe. If you want to get a high superior lathe that will not have to get upgraded in the future, connecting with a reputed heavy duty lathe machine manufacturer is a wise decision.

Heavy Duty Lathes

Heavy-duty lathes consist of high-quality components and implement new technologies. Various styles of heavy-duty lathes by lathe machine manufacturing companies include centre height, bed distance, maximum swing, spindle form, transit time, etc.

Heavy-duty lathes are extremely effective machine tools, particularly suitable for mass production. Heavy-duty lathes are suitable devices for metal grinding and metal spinning activities in the factory and also for steel making in repair shops, power plants, steel rolling mills, shipyards, paper mills, and also in the textile, mining, and energy sectors.

CNC & Heavy Duty Applications

For lathe clamping workpieces, it can get split into vertical lathes and horizontal lathes. The horizontal machine tool hooks the workpiece to the spindle joint. The spindle gets powered by a belt, a directly attached motor, or an integrated motor. The driving force defines much of the benefits of computing capacity.

Heavy-Duty Lathe Devices Get Explicitly Designed

The heavy-duty lathe is very well-designed, robust and can guarantee a longer lifespan and maximum efficiency in large-scale metal processing.

These ultra-modern devices are produced with advanced technologies and use comparatively little resources to produce higher quality performance.

Heavy-duty lathes are usually used for high-end machining operations. Also, heavy-duty lathes can perform several tasks on hard sheet metal and deliver the high-precision output, and heavy duty lathe machine prices are also very reasonable.

High Duty Lathe Deals with Metal Parts

The most demanding aspect of the management of heavy-duty workpieces is the precision of the shaping or deforming proportions. Specific precision in the manufacturing of cast iron and aluminium workpieces is challenging to obtain, so another workshop machinery is typically used to solve these problems.

Given job problems and safety concerns, several machines have been placed on the market to carry out the challenging part of metal processing.